How should the manufacturing sector respond as global uncertainty threatens the free flow of material and information? At Manufacturing World Japan 2025, held July 9 to 11 at Makuhari Messe, technology and connectivity leader NTT DATA advanced the industry conversation on resilience in the face of disruption, with a focus on two intersecting ideas: the agile supply chain and concurrent engineering.

The executive view: A new role for IT amid uncertainty

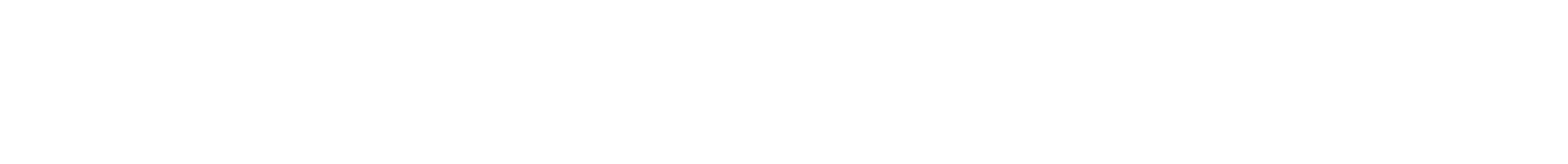

New problems require new solutions. NTT DATA Senior Vice President Ryoichi Anchi sees AI and other new technologies as key to mastering the new business environment.

“Historically, IT has largely focused on optimizing stable internal systems,” says Anchi. “The key theme going forward will be flexibility and resilience in unpredictable conditions.”

A modular approach combining multiple smaller systems of different types, says Anchi, is one way to avoid a single point of failure.

“NTT DATA’s global presence lets us cross-pollinate the best ideas and technology from around the world to help clients seize the opportunities that a new paradigm for manufacturing offers.”

Building the digital factory: Faster, smarter and more connected

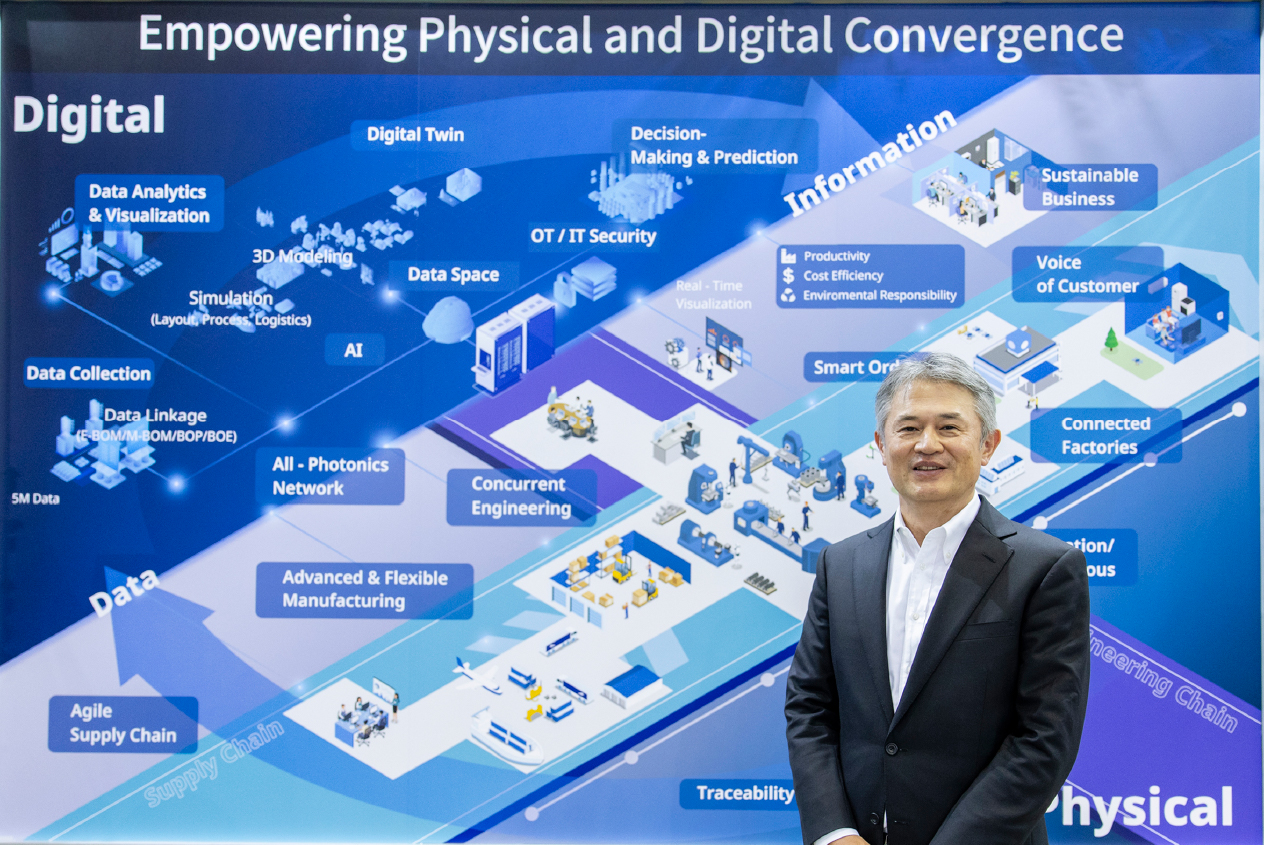

Throughout its Manufacturing World Tokyo 2025, NTT DATA shared its vision of manufacturing’s future: digital factories combining AI with advanced robotics to reach speed, efficiency and quality benchmarks that were unimaginable a generation ago. This intersection of the digital and the physical will be largely enabled by agile supply chains and concurrent engineering.

An agile supply chain can understand, think and react in real time, minimizing disruptions and other impacts from unpredictable events. To make this vision a reality, NTT DATA deploys Blended AI, a combination of the Smart AI AgentTM framework, which includes more than 50 features developed to support companies in their AI digital transformation, and the SyntphonyTM Autonomous Supply Chain manufacturing solution, applicable in case of time-critical processes with short lead times and multiple interconnected steps that require real-time access to data and smart decisions. This delivers visibility across the entire supply chain, along with speed and efficiency gains from automation and autonomy that allow potential issues to be identified and remedied before they have downstream effects. Thanks to this framework, NTT DATA can support companies in their entire value chain transformation journey, from value identification (advisory and consulting) to value realization (design, implementation, support and adoption).

Concurrent engineering is a transition from the linear “waterfall” model of product development to a new paradigm in which every part of the process ー from conceptualization to production line planning ー takes place at the same time. Designers can quickly iterate through virtual prototypes and get instant feedback from other functions. Production lines can be simulated and tested using digital twin technology before the factory is even built.

This is made possible with the application of NTT Data’s Smart AI Agent framework, in which multiple AI agents with different specializations and areas of responsibility act independently under a high-level “Supervisor AI” that coordinates and integrates their actions. This modular, multi-agent model makes the Smart AI Agent framework applicable not only to particular areas like concurrent engineering but also extensible to entire factories ー or even entire manufacturing departments. Everything from custom shift scheduling agents to “Meister AI” production agents can be added to the system as they come online, with client data used for training, fine-tuning and testing to smooth the transition.

To seize these opportunities, companies will need reliable data in high volumes and a broad-ranging, agnostic approach to AI, choosing the right tool for each job. GenAI’s ability to process and synthesize information and Agentic AI’s ability to identify and solve problems are both essential. NTT DATA is already combining these and other modalities with its Syntphony/Smart AI Agent platform to create blended AI solutions tailored to customer needs.

Keynote Session:

Transforming the digital supply chain in the new AI era

The centerpiece of NTT DATA’s presence at Manufacturing World Tokyo 2025 was a keynote session where Jordi Vilardaga, the Spain-based head of NTT DATA’s Supply Chain Center of Excellence, discussed real-life digital supply chain solutions with industry leaders from Japan and the United States.

Moderator Ariki Ono, Chief Digital Officer of Tokio Marine dR, opened with a summary of the challenges ahead. Manufacturers today face rising disruptions of every kind, from tariffs and war to “once-in-a-century” extreme weather events that now come yearly. Since unpredictable events by definition cannot be planned for, the only rational response is resilience ー but what does that mean in practice?

NTT DATA’s answer is agile supply chains powered by Blended AI. “What agile means here is the ability to see things as they happen, understand them and react flexibly,” explained Vilardaga. One piece in the puzzle is automation and autonomy, which lets humans move up to higher value-added tasks; another is increased visibility, which enhances the quality of decision-making throughout. All this can be achieved through blended AI solutions scaled up from “proof of value” projects with specific, testable goals and a business purpose as a trigger.

Nikhil Narvekar, global Chief Technical Officer of vertically integrated packaging manufacturer Graphic Packaging International, spoke of that company’s efforts to untangle the collection of incompatible ERP systems built up over years of acquisitions. Processing and merging the data from these systems into a single central data lake gave Graphic Packaging International a powerful tool for process improvement.

Case in point: purchasing. Existing processes, in which plant managers ordered parts based on their personal knowledge, were replaced with a consolidated approach that searched the data lake for the best possible price. “Doing this not only saved on costs, it also made us more agile,” said Narvekar.

Hiroaki Fukumura, an IT and digital solutions executive at automotive parts manufacturer Toyoda Gosei, shared insights from overseeing the 2023 launch of a flagship “smart factory” in southern China. The factory’s systems are built around a central “control tower” function that sucks up information from every part of the process and makes real-time decisions accordingly. “Our goal is to create a factory that never has to stop, even after a natural disaster,” he said.

Both Narvekar and Fukumura expressed ambitious goals for the future. Narvekar saw the potential for eliminating downtime entirely by using AI to handle preventive maintenance with no human intervention needed. Fukumura envisioned factories so smart that creating a defective product would be literally impossible.

Vilardaga was quick to point out the resonance between Narvekar and Fukumura’s stories and the solutions under development at NTT DATA. For example, NTT DATA’s Inbound Task Manager builds on “control tower” functionality like Toyoda Gosei’s to track all incoming shipments, scan natural-language emails and other information sources to identify potential bottlenecks and delays, and assign humans to take action as necessary.

Ono wrapped up the discussion by offering three main takeaways. First, an agile supply chain is above all designed to never stop moving. Second, data is key: AI-powered systems are no better than the data they receive. And third, a place remains for humans in the loop. Agile supply chains will empower manufacturers like never before. Human ingenuity will channel that power into bold action to seize the opportunities ahead.

Solution Dept. 2, Toyoda Gosei

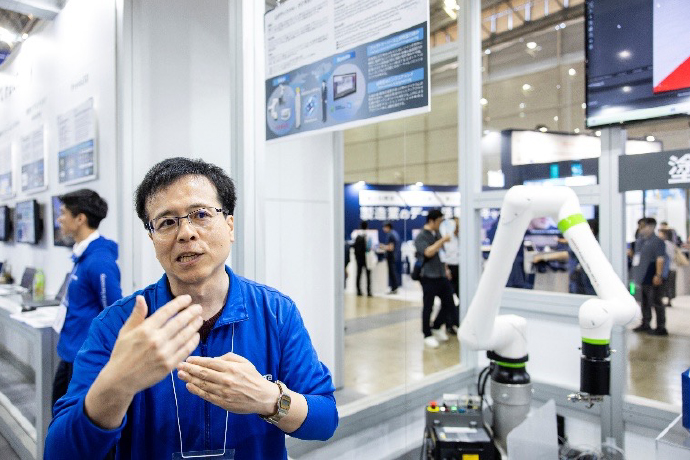

Digital twins: A tool for concurrent engineering

Concurrent engineering draws heavily on IT solutions to replace prototyping and trial runs in the real world. NTT DATA’s digital twin technology, created in partnership with Nvidia Corporation, is one example. Each “digital twin” is a virtual simulation managed by a backstage AI network and corresponding to a particular piece of real-life equipment.

In the “real-to-virtual” direction, motion and other data from the real-life equipment is used to synchronize the digital twin to it with millimeter-scale accuracy. Because the digital twin precisely mirrors the facts on the ground, it allows geographically separated team members to collaborate on detecting, diagnosing and remedying issues.

But once a digital model is available, the AI network can also take the next step and simulate equipment that does not yet exist. This is the “virtual-to-real” application of digital twin technology. Factory designs can be tested and compared years before construction is set to begin, and robots programmed and tested in virtual space can be ready to go on day one.

The same framework can be applied to product development and design. With “digital product development,” new and revised product designs, including geometry and property data, can be created by product designers and shared with production engineers configuring production equipment. These digital twins can be used to evaluate feasibility and equipment requirements for the production process before the design cut-off point, without making or testing prototypes using real materials.

NTT DATA estimates that its digital twin solutions will reduce manufacturing costs by as much as 40%, but the reduction in time to market would be even more significant. Manufacturers could release new products and update old ones with unprecedented speed. Here, too, blended AI has a role to play, from GenAI writing code to Agentic AI searching for greater efficiencies. Ultimately, this could lead to autonomous engineering, with humans instead focused on establishing overarching goals and directions.