Review

ABeam Consulting

Helping Vietnamese Companies to Monitor Their GHG Emissions

Shuhei Toyoshima

Director, ABeam Consulting Ltd.

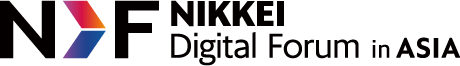

GX Concierge is a service that helps companies to addresses the need for green transformation (GX) by providing total support for cutting GHG emissions, from visualizing emissions to formulating emission reduction plans. Shuhei Toyoshima, the director of ABeam Consulting (hereinafter “ABeam”) responsible for the service explained: “Through our long-term work on GX, even before we released the service, we identified three essential points that need to be considered.”

Toyoshima listed them as strategy, full use of digital technology, and co-creation. On strategy, he noted the importance of taking into account regional conditions in ASEAN (Association of Southeast Asian Nations) and the rest of Asia.

On the current regulatory environment, he said: “Regulations are getting more and more detailed, as Europe continues to introduce new rules, such as requirements for disclosure of GHG emissions on a product-by-product basis.” While these regulations may be suitable for Europe, where electric power decarbonization is relatively well advanced, they are difficult to apply as they are to ASEAN or the rest of Asia, where large quantities of coal-fired power continue to be used. According to Toyoshima, countries and regions need to set their own roadmaps for cutting GHG emissions as they catch up with global trends.

In following the roadmap, there will be a variety of challenges, but how to overcome them will depend on the situation. Toyoshima pointed out that “to grasp and manage complex and diverse issues and their solutions, it is vital to take full advantage of digital technology,” referring to the second point mentioned above.

On the third point, co-creation, he continued: “To cut GHG emissions, it is necessary to work across entire supply chains, so ‘co-creation’ with various other companies and stakeholders is indispensable.”

Reflecting on ABeam’s co-creation with Sumitomo Corporation in providing the GX Concierge service, he described it as “a very positive experience.” He attributed this to the fact that the two companies put together a team of people with a wide range of values and abilities, and were able to focus clearly on the goal of carbon neutrality with an approach that embodied diversity.

Concluding his discussion of these three essential points, Toyoshima said: “I think that they can also be useful in tackling challenges other than GX.” Summing up, he continued: “I feel that even events like this one in Hanoi are helping to increase diversity. I really hope that we can all work together at the leading edge of this digital revolution to open up Asia to the wider world.”

Rising GHG emissions are also an issue in Vietnam

Managing Director, ABeam Consulting (Vietnam) Co., Ltd.

Ryohei Oda of ABeam Consulting (Vietnam) offered a presentation about GHG emission reductions in Vietnam.

Oda noted that China is currently the world’s largest emitter of CO2, followed by the United States, India, and Russia. Japan currently ranks fifth, accounting for 2.88% of total global CO2 emissions in 2021.

Vietnam also needs to cut its GHG emissions. Since the Doi Moi economic reform policies were started in 1986 to shape a more market-oriented economy, GHG emissions have risen steadily in line with rapid economic development. Oda reported that Vietnam is responsible for 0.88% of total global CO2 emissions.

The Vietnamese government has responded by declaring its commitment to a carbon neutral future, pledging to cut GHG emissions to zero by 2050. As a transitional goal, it has also committed to cutting its GHG emissions by 43.5% compared to the business as usual scenario by 2030.

To help achieve this goal, the government has obligated 1,662 designated companies to submit “GHG Inventory Reports” detailing their GHG emissions starting in 2025. In 2027, the companies will also be required to start reporting their emission reduction efforts. As Oda explained: “The idea is that if individual companies achieve zero carbon emissions, Vietnam will be able to achieve carbon neutrality as a nation.”

Helping Vietnamese companies to monitor their GHG emissions

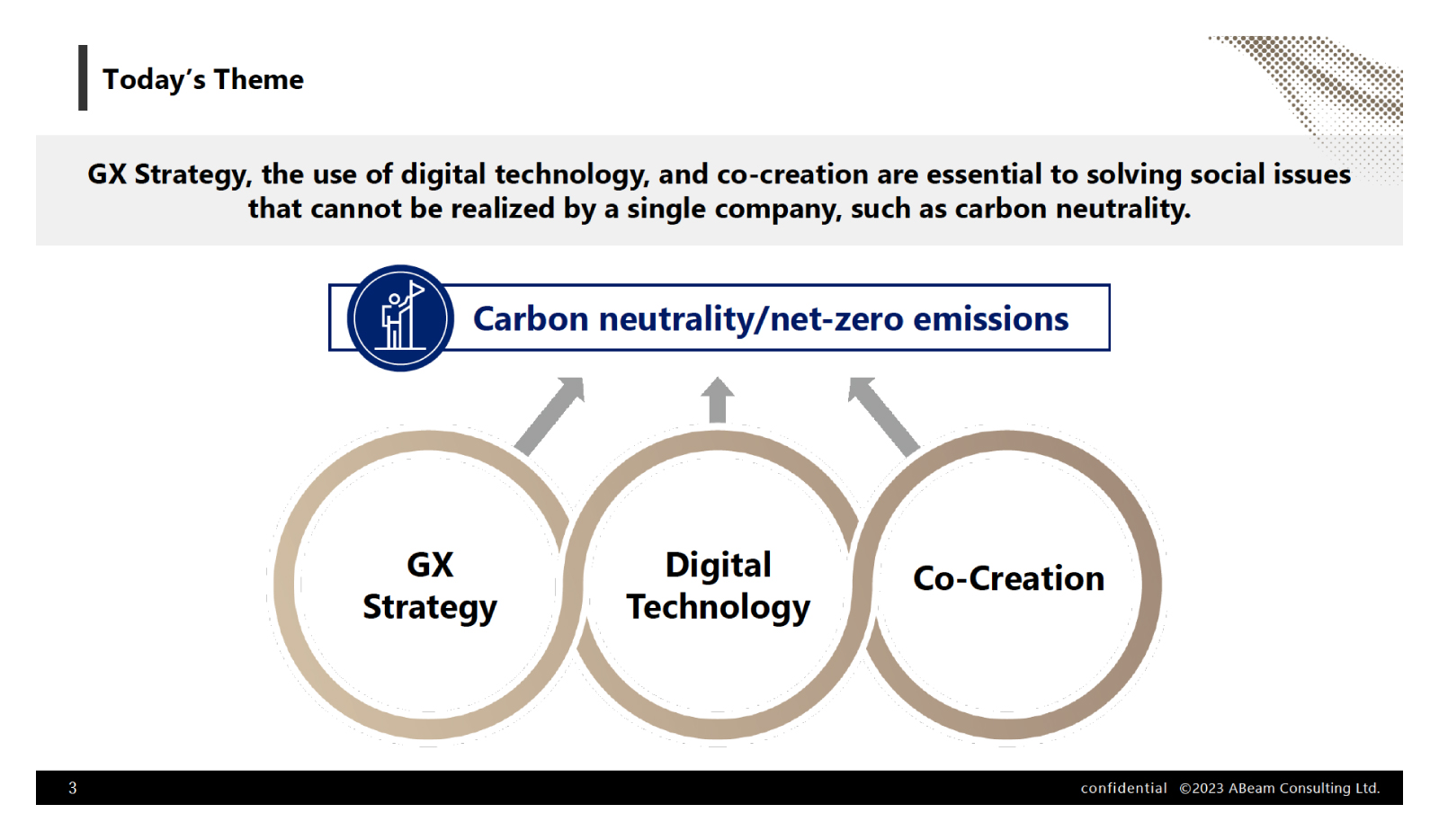

The GHG emissions for these GHG Inventory Reports are categorized into three “scopes.”

Scope 1 emissions are the GHGs emitted directly by the company at production plants, in manufacturing processes, in product transportation, etc.

Scope 2 emissions are the GHGs emitted in the process of generating the electricity that is used, while Scope 3 emissions are indirect GHG emissions from the use of products and services that are sold, and from the production of purchased raw materials.

Oda outlined the efforts of a Vietnamese company he worked with to help in monitoring Scope 1 GHG emissions relating to the transportation of products.

Previously, the company’s data entry staff had to collect receipts for gasoline purchases from truck drivers, along with information about transported products, and distances traveled, etc. and enter it manually into a computer. Summaries created from the entered data then had to be approved by a manager.

Oda explained: “Many Vietnamese companies follow this method, but collecting data is a laborious task and manual data entry typically results in many errors. The summaries that are created are often hard to understand, so managers who have to review data cannot verify it with any precision.”

To solve this problem, ABeam created a simple application using Microsoft 365, which the company was licensed to use. “We formatted the application so that truck drivers, or others standing in for them, can enter data directly,” said Oda. “We have automated the whole process, from collecting data to creating summaries.”

The summary has also been simplified to allow managers to make quicker decisions. “Although the system is very simple, it dramatically reduces the number of input errors and the time needed to prepare a GHG Inventory Report,” said Oda.

Since the GHG Inventory Report is only a means of monitoring current GHG emissions, other initiatives are needed for cutting emissions. Oda explained: “It is essential to formulate a strategy or roadmap for carbon neutrality, implement it, monitor its effectiveness, correct anything that is not working, implement again, and repeat. This kind of PDCA cycle is important.” ABeam offers a variety of services to assist with this process and is happy to answer any questions from interested companies.